After months of research, speculation and delays, South Korean energy giant LG Energy Solution said on March 24 that it will build a $5.5 billion lithium battery manufacturing plant in Queen Creek this year, with production starting in 2025. Announced.

Town officials have been waiting for a launch date for nearly a year, and LG’s announcement is a surprising development for the town.

That’s because the company quadrupled the $1.4 billion investment it first announced last April.

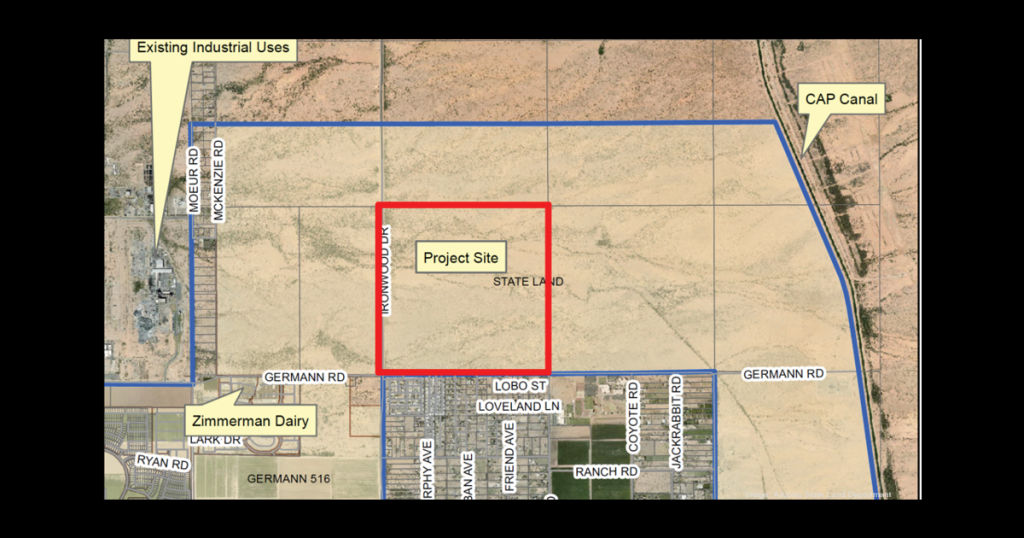

LG’s North American subsidiary purchased 650.5 acres of Ironwood Road and German Road for $84.4 million last April at a Homestead auction, and the town is upgrading roads around the site in anticipation of development.

The bid was the only cast for the State Trust Land parcel located southeast of Phoenix Mesa Gateway Airport, near Zimmerman Dairy Farm and CMC Steel Arizona.

Queen Creek Mayor Julia Wheatley said:

“Large-scale investment will create positive ripple effects for the region and the state, bringing in local jobs, infrastructure and capital investment,” said the mayor, adding, “LG Energy Solution will start construction along the advanced manufacturing corridor. We will be the first company to do so,” he added. ”

The significant expansion of LG’s plans has caused some panic among Queen Creek officials as they begin reviewing plans already in place for additional infrastructure work around the site. Pinal County will likely need to review last year’s air quality permit approval because the company is building not one but two plants on the site.

According to LGES, this is the single largest investment in an independent battery manufacturing facility in North America.

It will consist of two facilities, one for 2,170 electric vehicle batteries and one for “pouch-style” lithium-ion phosphate batteries used in rechargeable devices such as power tools and e-bikes.

“Our decision to invest in Arizona marks our strategic initiative to continue expanding our already largest global manufacturing network to further advance our innovative, top-quality products at scale and speed. A press release of LG Energy Solutions.

“We believe this is the right move at the right time to boost the clean energy transition in the United States.”

LGES said the battery factory will bring the company closer to its customer base and save money on logistics and manufacturing as demand for rechargeable batteries grows in North America.

In addition to being a huge investment, LGES also plans to install new technology at its facility, making production decisions based solely on data. The company says these cost savings will ultimately lower the cost of electric vehicles.

LG ES said, “By implementing this important measure to improve product quality, our Arizona facility will be able to increase yields, improve manufacturing processes, and increase productivity to meet the growing demand for batteries in the region.” We aim to do well.”

LGES first announced its intention to build a facility on Queen Creek almost a year ago. However, months of speculation and research ensued as the company said it was re-evaluating.

Progress stalled and there was speculation that the facility would never be built. It ended with an announcement on March 24th.

“Arizona has become the battery manufacturing capital of the country,” Gov. Katie Hobbs said in a statement.

“These Arizona-made batteries will power green, sustainable technologies around the world and will solidify Arizona’s reputation as a renewable energy innovation hub. And thank you for your commitment to providing thousands of well-paid jobs for the people of Arizona,” she added.

According to LGES, the company’s decision to increase its investment in electric vehicle battery production in North America means it will invest in locally manufactured, high-quality, high-performance batteries to meet the Inflation Reduction Act tax credit for electric vehicles. This is due to the increasing demand from electric car makers like Tesla. .

“By locating the new ESS battery facility in North America, the world’s largest ESS market, LGES will address the rapidly growing need for locally-manufactured batteries behind the IRA and accelerate the drive for clean energy in North America. We aim to further facilitate the transition through government policies to support ESS adoption,” the company said.

The LGES announcement is the latest in a string of battery-related announcements taking place across Arizona and across the country. A wave of new factories is expected to increase battery manufacturing capacity in North America by a factor of ten from 2021 to 2030.

LG didn’t start out as a giant electronics and battery manufacturing conglomerate.

Lucky Chemical was founded in 1947 as a cosmetics company. According to a Newsweek report on LG’s history, when the company opened a research lab in South Korea in the 1950s, its first star product was called Lucky Cream, which used plastic injection technology to produce a plastic comb and soap dish. was manufacturing

Town officials say it’s good for the local economy, but neighbors worry that building the facility could damage the environment and pose a threat to people, pets and livestock. This is causing concern among