Ford’s $2 Billion Investment in Electric Vehicles

LOUISVILLE – Ford Motor Company has announced it will invest nearly $2 billion to create electric vehicles (EVs) from a new adaptable platform, with plans to launch a medium-sized EV pickup truck by 2027.

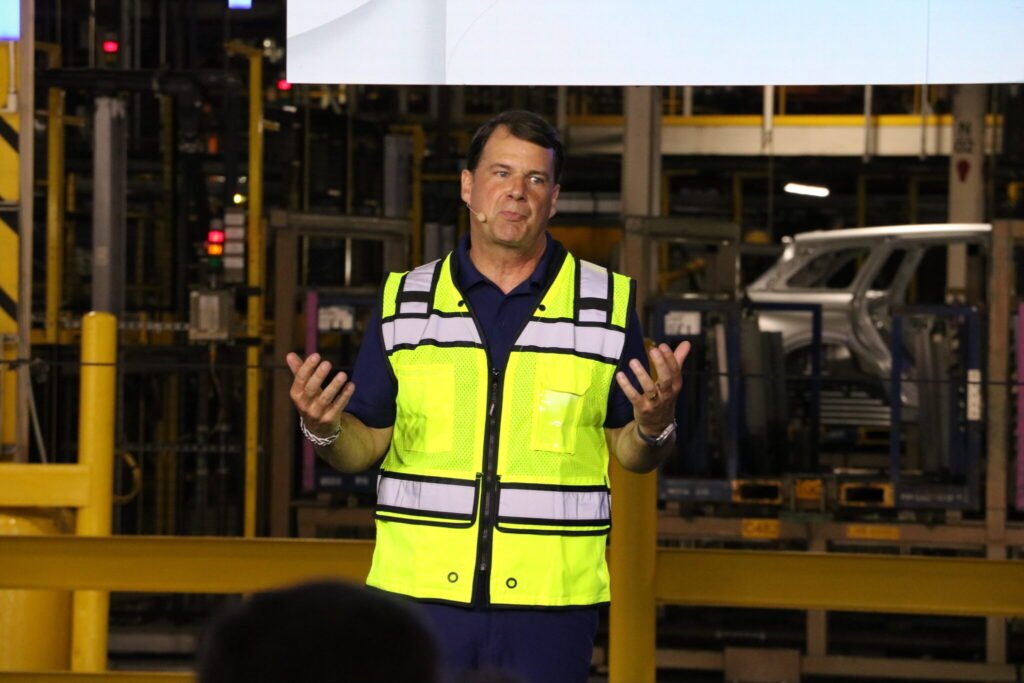

During a recent gathering at the Louisville Assembly Plant, Ford president and CEO Jim Farley highlighted the importance of this “universal” EV platform, noting that while it poses risks against global competition in the EV market, the investment is essential for the future. He emphasized the need for affordable vehicles that satisfy customer demands while ensuring sustainability and profitability, all done with American labor.

The starting price for the EV truck is set at $30,000, featuring impressive range. The truck will be produced on a newly designed assembly line at the Louisville factory, with EV batteries supplied from a Michigan plant. Farley explained that this new truck has about 20% fewer parts compared to traditional vehicles, which will not only speed up assembly but also reduce physical strain on workers.

Farley shared the stage with Kentucky Governor Andy Beshear, who praised the substantial investments in the state. Beshear’s office indicated that the transformation of the Ford plant marks one of Kentucky’s largest economic development endeavors.

Beshear stated, “This cutting-edge platform will be the foundation of the next generation of vehicles. The best part is that these vehicles are affordable.” He believes these affordable options will help many American families save money on essentials like groceries and school supplies.

However, the transition to the new EV assembly line may result in job shifts. The local United Autoworkers leader mentioned that some workers from the Louisville plant may be relocated to other Ford facilities. Currently, the plant produces SUVs like the Ford Escape and Lincoln Corsair.

Brandon Reijerter, chair of the Union at the Louisville assembly plant, commented that the changes weren’t as drastic as some had feared. He expressed hope that while employment numbers might change, no one would be left without a job.

Reisinger shared that some assembly work for the EVs will take place at the plant itself, aiming to mitigate job losses. Following the conversion, he estimates a reduction of hundreds in the workforce, due to retirements and changes in roles. Ford has committed to securing 2,200 jobs during this transition, even as the current workforce at the factory is about 3,300.

Reisinger anticipates that the conversion could start by the end of this year, although temporary unemployment for some workers may occur during the transition. Fortunately, union contracts provide supplemental unemployment benefits that cover about 80% of lost wages.

When addressing the political challenges posed to electric vehicles, Reisinger pointed out the cost-effectiveness of charging EVs compared to traditional gas prices as a strong argument for their adoption. He mentioned, “When we start building, I’m going to buy one of these too. It’s going to be a very cost-effective vehicle to drive.”